Professional Middle Size Box Industrial Checkweigher is a special equipment in modern automated production workshop, mainly used for weight supervision and inspection of various production line products.Dynamic Check Weight Machine checks whether the weight of the product is qualified,whether there is overweight or underweight,a small amount of accessories,etc., qualified products will automatically flow out from the next working link,and unqualified products will be automatically rejected or alarmed.Welcome to consult for quotation information!

Type SG-450

Weighing Range 0.05-20/30kg

Limited of product L: 500 W:450 H: 3-400mm

Accuracy ±1g

Division Scale 0.1g

Belt Speed 0- 40 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 100kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

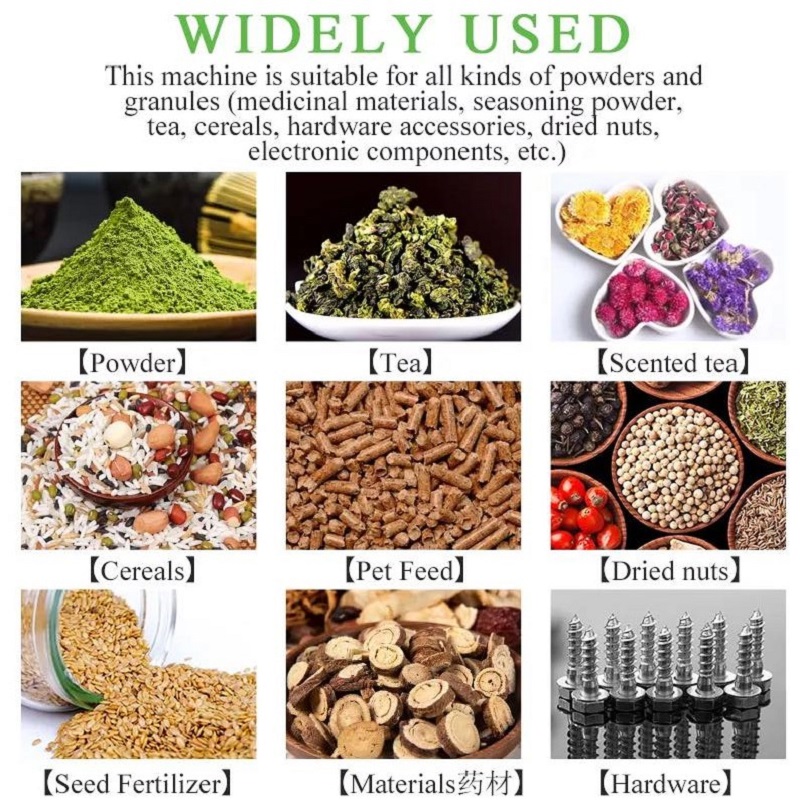

* Strong versatility

The standardized structure of the whole machine and the standardized human-machine interface can complete the weighing of various materials.

* Easy to operate

Man-machine interface, fully intelligent and humanized design; the conveyor belt is easy to disassemble, install and maintain, and is easy to clean.

* Adjustable speed

The motor is controlled by frequency conversion, and the speed can be adjusted as required.

* High-speed and high-precision

Using high-precision digital sensors, fast sampling speed and high precision.

* Zero tracking

Can be manually or automatically cleared, and dynamic zero tracking;

* Interface function

Reserve a standard interface, which is convenient for data management, and can communicate with PC and other smart devices.

* Self-learning

After creating new product formula information, there is no need to set parameters. Use the self-learning function to automatically set equipment suitable parameters, and store them to facilitate the next time you switch products.

This product is mainly suitable for the weight detection of heavy and bulky items,especially for the detection of missing items in the whole box; such as: missing bottles, missing boxes, missing pieces, missing pieces, missing bags, missing cans, etc.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Q1. Are you a manufacturer or trader?

A: We are a manufacturer and we are located in Shanghai,China. We have our own design team for product design.

Q2. What are your company's requirements for payment terms?

A: TT,L/C,Western Union,Money Gram,Paypal,International Credit Card.,

Q3: Can you explain the whole transaction process?

1. Understand the specific needs of customers and determine the machine details.

2. Sign the contract.

3. Pay the deposit.

4. The factory arranges production.

5. Test and inspect the machine before shipment.

6. Check by customers through online or on-site testing.

7. Shipment and transportation, balance payment.

Q4. What kind of shipping method can you provide?

A: By sea, by air and by international express.We will send the photo and video of machine to customer to check the machine running situation before delivery.

Q5. Do you accept customer logo and customization?

A: We accept all kinds of customization and logo for our customers for all our products.

Q6. How about the packing for product? Is it easy damaged during transportation?

A: No.We takes of wooden case and it is very safe.

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference.Thank you.

●What product?

●Product weight?

●Product size?

●Speed requirement?

●Accuracy requirement?