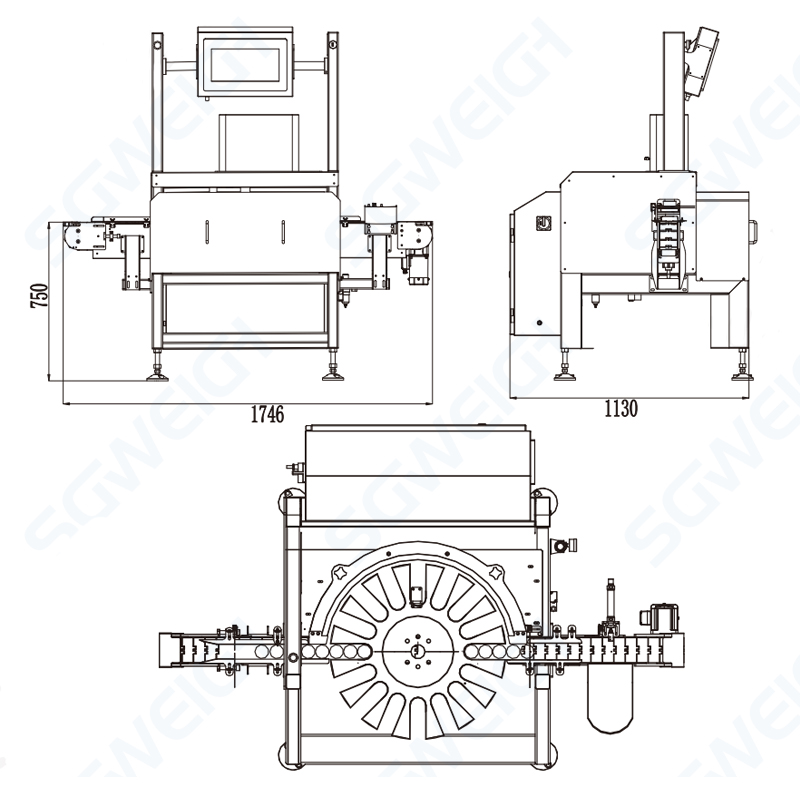

Rotary Bottle Checkweigher is a type of checkweighing machine specifically designed for the pharmaceutical, food and beverage, and other industries where accurate weight measurement of bottles is crucial.

Here's an overview of how a rotary bottle checkweigher typically works:

Feeding System:

Bottles are fed onto a rotary table or conveyor system, which moves them through the checkweighing process.

Weighing Mechanism:

As each bottle moves through the checkweigher, it passes over a weighing platform or scale. The weighing mechanism captures the weight of each individual bottle.

Weight Comparison:

The measured weight is then compared to a predefined target weight. If the bottle's weight falls outside the acceptable range, the checkweigher triggers an alert or takes corrective action, such as rejecting the bottle from the production line.

Sorting/Reject Mechanism:

If a bottle is found to be under or over the specified weight, it may be automatically sorted and rejected from the production line. This is often done using mechanisms such as air jets, pushers, or mechanical arms.

Integration with Production Line:

Rotary bottle checkweighers are designed to seamlessly integrate into existing production lines. They can be synchronized with other machinery to maintain a continuous and efficient production process.

Key advantages of using rotary bottle checkweighers include:

High Throughput:

Rotary designs allow for continuous and efficient processing of bottles.

Accuracy:

Checkweighers are capable of precise weight measurements, ensuring compliance with regulatory requirements and product quality standards.

Automation:

The automated sorting and rejection of non-compliant bottles contribute to increased efficiency and reduced manual labor.

Data Collection:

The ability to collect and analyze data helps manufacturers monitor and improve their production processes.

When selecting a rotary bottle checkweigher, factors such as production speed, bottle size variability, and the required level of accuracy should be taken into consideration. Different industries may have specific regulations and standards that need to be met, so it's essential to choose a checkweigher that aligns with those requirements.

Hot Labels

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Vertical Metal Detector

Checkweigher and Metal Detector Combo

Convenient Checkweigher

Weigh Labeling Machine